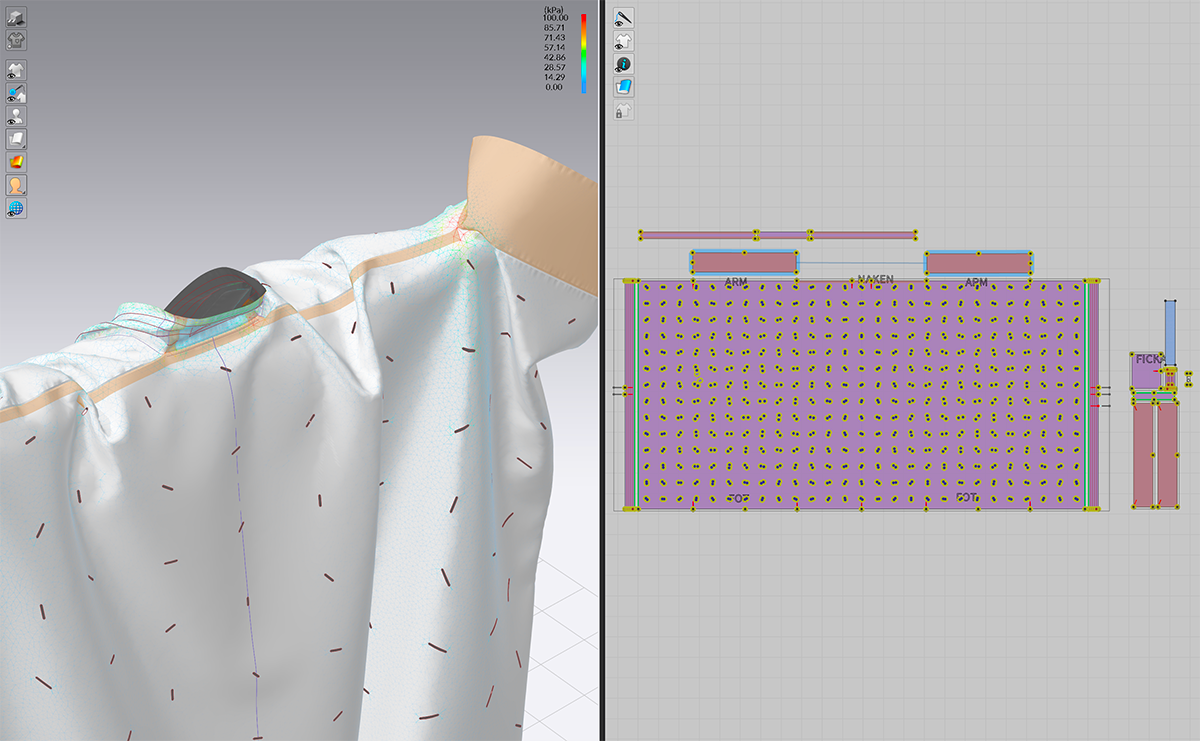

Rapid prototyping with CLO for the apparel industry

CLO software can be a great ally for rapid prototyping for apparel. From fashion to sport industry.

When it comes to 3d modeling of clothing, a very wide scenario opens up. We can test the correctness of the paper pattern, see the graphic rendering of the prints on the garment, generate photorealistic images, and create dynamic video outputs such as turntables, which I will discuss at another time.

The stages of the project

But there is more. As part of the in-depth course on CLO 3d held at WeMake, I experienced the transversality of the famous software in communication with the laser cutting machine by setting as my goal the rapid prototyping of clothing.

I decided to base the project on the paper pattern shared by atacac, a Swedish fashion studio that believes in digitizing the creative process for fashion.

I wanted to exploit the characteristic movement of the laser head with the execution of decorative cuts coordinated in a parametric pattern made ad hoc by ALIGN OFFICE, a design studio oriented to software experimentation across different sectors.

Calibration of the laser head, as well as communication between cad software and cam machine language, are key steps in moving from digital to physical prototype. The entire development process was supervised by Sara Savian, a designer who specializes in digital fabrication and wearable technology, among other things.

After quickly laser-cutting the fabric, I packed the prototype with a straight machine and made the photo shoot.

A glimpse into the future

The experience of digital fabrication for apparel has given me confirmation that the tools of 3d modeling, laser cutting, and the ability to pack a prototype are a great resource for designers, companies, and artisans.

This is manufacturing 4.0 for apparel! Ability to facilitate visual representation of creative proposals. Speed of communication with the customer, rapid creation of garment tests and automation in the creation of variants.

But also a great opportunity to return to handcrafted quality garments by new means. Development of on-demand production with handcrafted quality, enhancing Italian manufacturing know-how. The possibility of producing the quantities really needed for sale, without making large stocks.

Credits

Project & Making

Parametric Design

Supervisor Designer

Paper Model

Laser Cut

Technical Support

Photography